| |

|

Stanton W. Mead Education and Visitor Center

|

|

Sustainable Design Features

|

|

Click on the images below to see an enlarged view

|

|

|

|

LEED Green Building

Rating System

|

Sustainable Building Strategies & LEED certification

The Mead facility has been designed to comply with standards of the LEED green building rating system, which was

developed by the U.S. Green Building Council for certification purposes. The LEED criteria are divided into 5 categories:

- Sustainable Sites

- Water Efficiency

- Energy & Atmosphere

- Indoor Environmental Quality

- Materials & resources

Selected sustainable design measures employed in the design and construction of the Mead facility include:

- reduced site disturbance at building, site access roads, parking & utilities to reduce erosion;

- panelized construction to reduce construction waste;

- on-site construction waste management, with 95% recycled and diverted from landfill;

- reduced energy load and renewable energy sources for heating & cooling;

- cut-off exterior lighting fixtures to eliminate glare and light pollution;

- operable windows for light, views and ventilation;

- physically-isolated and separately-ventilated janitor and copier rooms for indoor air quality;

- fundamental Building Commissioning for optimal system performance;

- Zero Net Energy goal, based on intermittent occupancy patterns.

|

USGBC

|

|

|

|

|

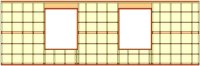

Standard 2x wall

Interior-strapped 2x wall

|

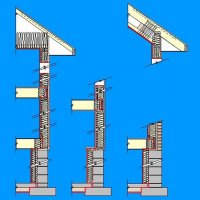

High Performance Building Envelope

The Mead facility was built with a variation on standard wood-frame construction, modified for airtightness and

thermal separation, including:

- interior strapped-wall construction, consisting of 2x6 structural stud walls with an added layer of horizontal

2x2 and 2x4 strapping across the inside face of the studs to provide a thermal break, reduce the ratio of solid

framing to cavity insulation and provide a 7" insulated cavity;

- airtight/superinsulated construction with wood-frame construction details modified for air-sealing;

- recycled-content wall-spray cellulose insulation in wall cavities;

- heavily-insulated concrete foundation & slab floor, with hydronic- radiant heat distribution;

- raised-heel cantilevered wood-frame truss system to allow for increased levels of attic insulation;

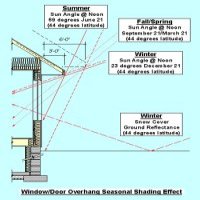

- extended roof overhangs sized for winter sun penetration and summer sun shading;

- recycled-content blown cellulose attic insulation; taped and sealed interior vapor-barrier;

- airtight electrical box enclosures to ensure integrity of wall vapor-barrier;

The projected energy savings, from incorporated energy-conservation measures, is estimated at 73% better than

a similar building built to meet model energy codes.

|

Air-tightness Details

|

|

|

|

|

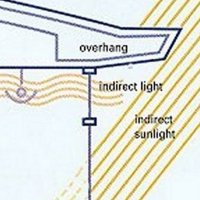

Cool daylighting

|

Cool Daylighting & Advanced Lighting Controls

The Mead facility employs a number of natural and advanced lighting techniques, including:

- ceiling heights tied to height & location of transom windows;

- exterior overhangs sized to reduce glare, overheating and to reduce cooling loads;

- interior transom windows to allow for borrowed light from adjacent spaces;

- interior ceiling finishes and configurations to allow for bounced-light penetration into the interior;

- interior wall finishes to allow for reflected light penetration and to reduce contrast;

- suspended direct/indirect pendant lighting lighting to provide diffuse ambient lighting;

- supplemental task lighting at workstations and task areas;

- daylight sensor-operated controls for lighting fixtures, both for cut-off and dimming purposes;

- occupancy sensor-operated controls for lighting in specific spaces;

- low-wattage fluorescent and compact-fluorescent lighting fixtures;

- L.E.D. low-wattage exit signs and other fixtures.

|

Overhang Shading Geometry

|

|

|

|

|

|

Controlled Ventilation

|

High-Performance Mechanical Systems

The Mead facility uses a variety of mechanical system strategies, including:

- non-CFC equipment to avoid atmospheric ozone depletion;

- individually-zoned controls for heating, cooling, humidity and ventilation;

- zone-controlled energy-recovery ventilation equipment for mechanical ventilation & make-up air;

- zone-controlled in-floor hydronic-radiant heat distribution;

- carbon dioxide monitoring for indoor air quality.

|

|

|

|

|

|

|

|

Green Building Materials

|

Environmentally-responsible Materials & Construction Methods

The Mead facility was designed to be built with an emphasis on:

- construction and installation practices to minimize contamination/degredation of materials and systems;

- recycled-content building materials and finishes, such as ceiling panels, wallboard, etc.;

- use of agri-board desktops and furniture;

- use of low or non-VOC finishes, sealants, adhesives, etc.;

|

|

|

|

|

|

|

Flush Valves & Faucets

|

Water-conserving Fixtures & Landscaping

The Mead facility uses plumbing fixtures and landscaping techniques to reduce water usage, including:

- water-efficient plumbing fixtures for water conservation;

- flush valves and faucets that employ self-charging hydro-powered micro-turbines that recharge their batteries

from water flow;

- low-flow and dual-flush toilets;

- bio-swales and retention ponds to reduce and treat runoff from the parking lot and building roof;

- non-irrigated drought-resistant plantings and restored prairie plantings to reduce water needs;

|

Dual-flush Toilets

|

|

|

Sustainable Design Resources

|

|

|